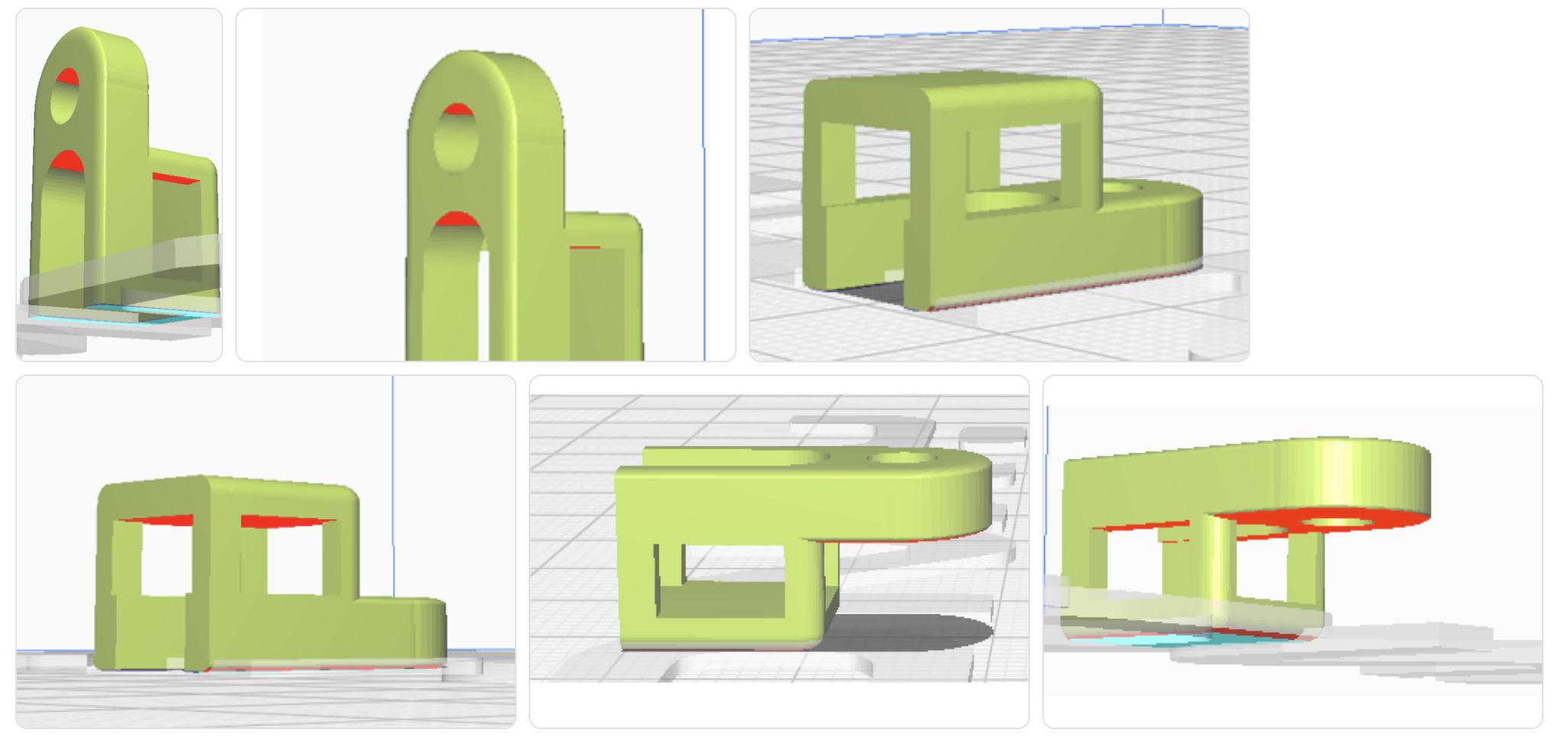

Optimizing part orientation for 3D printing

E

Hello, I am new to 3D printing and am trying to understand how to optimize part orientation to reduce the need for support structures and production times. Does anyone have effective tips/strategies for doing this? In particular, I’m considering a model similar to this https://www.printables.com/model/622078-screw-cable-zip-tie. Any advice will be greatly appreciated!

Automatically translated from: Italiano

See original

Suggested Topics

Topic

Replies

Views

Activity

Minimum embossed text size for TPU molding

Hey there, I'm designing a flexible watch strap that will be injection molded in TPU (Shore 85A). I want to include some small embossed text (branding and serial number) directly on the strap, but... read more

4

577

Dec 11

Printed bracket cracking – how to reinforce?

Hi, I'm prototyping a small bracket for holding a plastic cover in place—roughly 60 × 30 × 10 mm, with two hooks and two screw holes (M3) on the top side. I printed it in PLA with 20% infill... read more

1

158

Apr 23

FEA of a welded tow hitch

Hi! Need help on a welded tow hitch for an off-road vehicle using S355 steel tubing and 8 mm plates. It needs to handle a 3,500 kg towing load with off-axis forces. In ANSYS,... read more

1

201

Apr 10

Best gear setup for a compact robotic arm gearbox

Hi,Working on a compact gearbox for a robotic arm and need advice on the best gear setup. The arm sees intermittent loads, max torque at the output is 15 Nm, and I need about... read more

2

592

Apr 16

How to call out helicoils or inserts on a drawing?

Hey,My aluminum part needs reinforced threads, so I’m looking at using Helicoils or possibly another type of insert if the machinist has a better suggestion (I’ll have my part produced by an external manufacturer).... read more

1

234

Mar 31

Europe

Europe  Türkiye

Türkiye  United Kingdom

United Kingdom  Global

Global

Login with my Xometry account

Login with my Xometry account